The Brake Check Blog

Subscribe to our blog!

BLOG CATEGORIES

Yamaha Teams Up with Hayes Brakes for the 2025 RMAX 1000 UTV Line-Up

Maximize Performance & Minimize Costs: The Value of Expert-Led Custom Brake Development

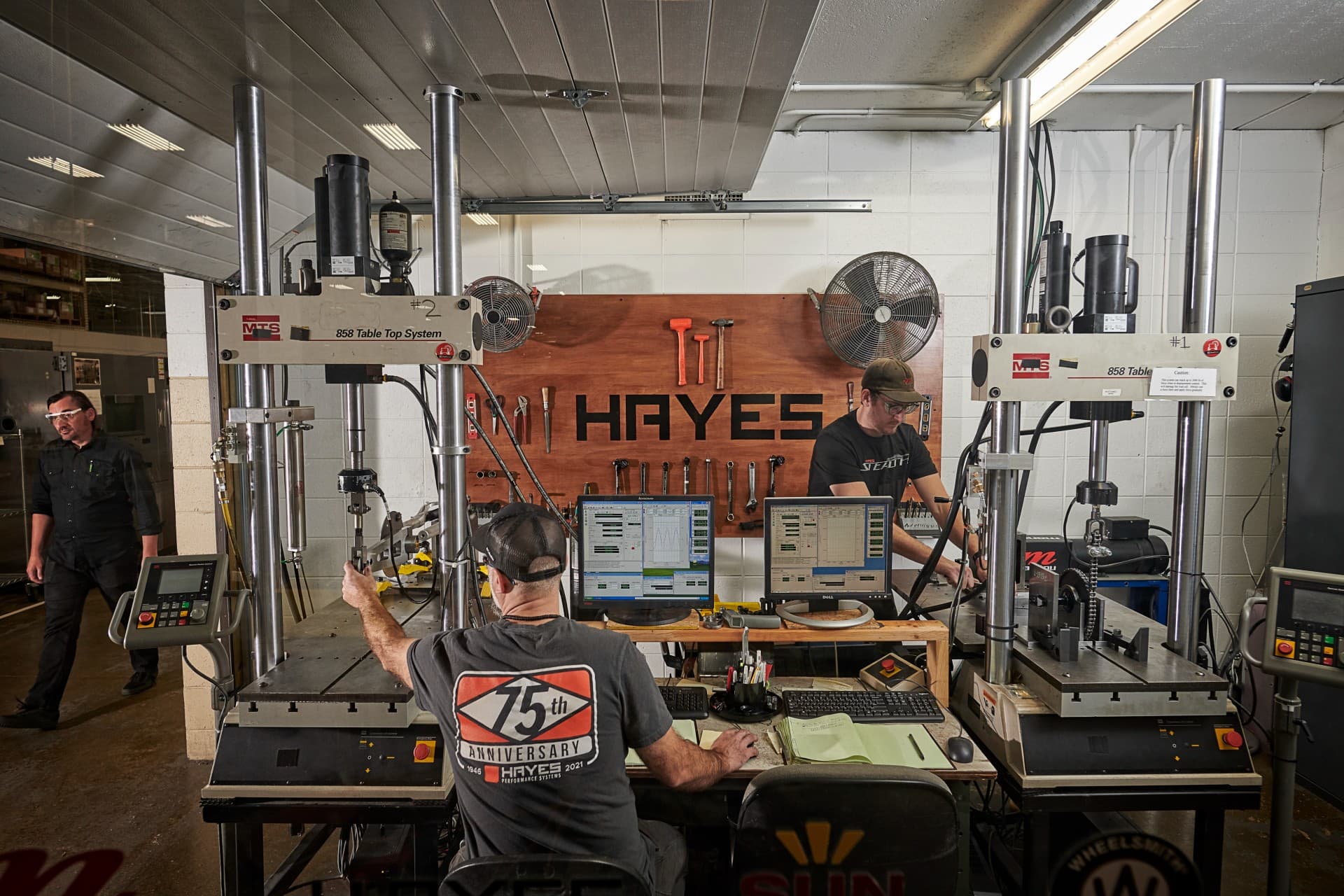

When OEMs partner with brake system specialists early in the vehicle design and development process, they unlock key benefits—most notably, faster time-to-market and better cost management. To understand the value Hayes delivers from the early stages and throughout the process, we need to look at that process and how each step helps OEMs achieve their performance and cost goals.

The Future of Braking: Why Expertise Matters in Integrating Advanced Electronics

Fortunately for today’s drivers and passengers, significant advancements have been made to improve vehicle safety, stability, and performance. Some of the most notable improvements include anti-lock braking systems (ABS), electronic stability control (ESC), traction control systems (TCS), and electronic parking brakes (EPB), all of which are electronically driven. These technologies were initially developed for passenger vehicles, but they’re now being applied to a wide range of on-road and off-road vehicles, including motorcycles, electric vehicles (EVs), SxSs and UTVs. This trend reflects a growing emphasis on sophisticated, safety-focused systems, even in vehicles not traditionally associated with such advanced features. Conceptually, these algorithm-based safety features operate similarly across various vehicles. However, designing, engineering, and preparing brakes for integration into different vehicles and systems requires a brake manufacturer with the expertise to meet the demands of increasingly complex vehicle architectures.

Electric Vehicles and Dry Disc Brakes: A Combination That Promotes Efficiency & Safety

Do electric vehicles (EVs) use the same brake systems as conventional vehicles? Yes and no. Some light EVs – ebikes and scooters, for example – rely primarily on regenerative braking systems. These vehicles are relatively lightweight and operate at lower speeds, making regenerative brakes sufficient for their needs. However, when a vehicle needs more stopping power, regenerative braking alone is often not adequate. That’s where dry disc brakes come in. Most of today’s EVs rely on dry disc brakes – alone or in combination with regenerative brakes – to provide the most efficient and safe braking. Let’s look at how each system works and how they work together in some EVs.

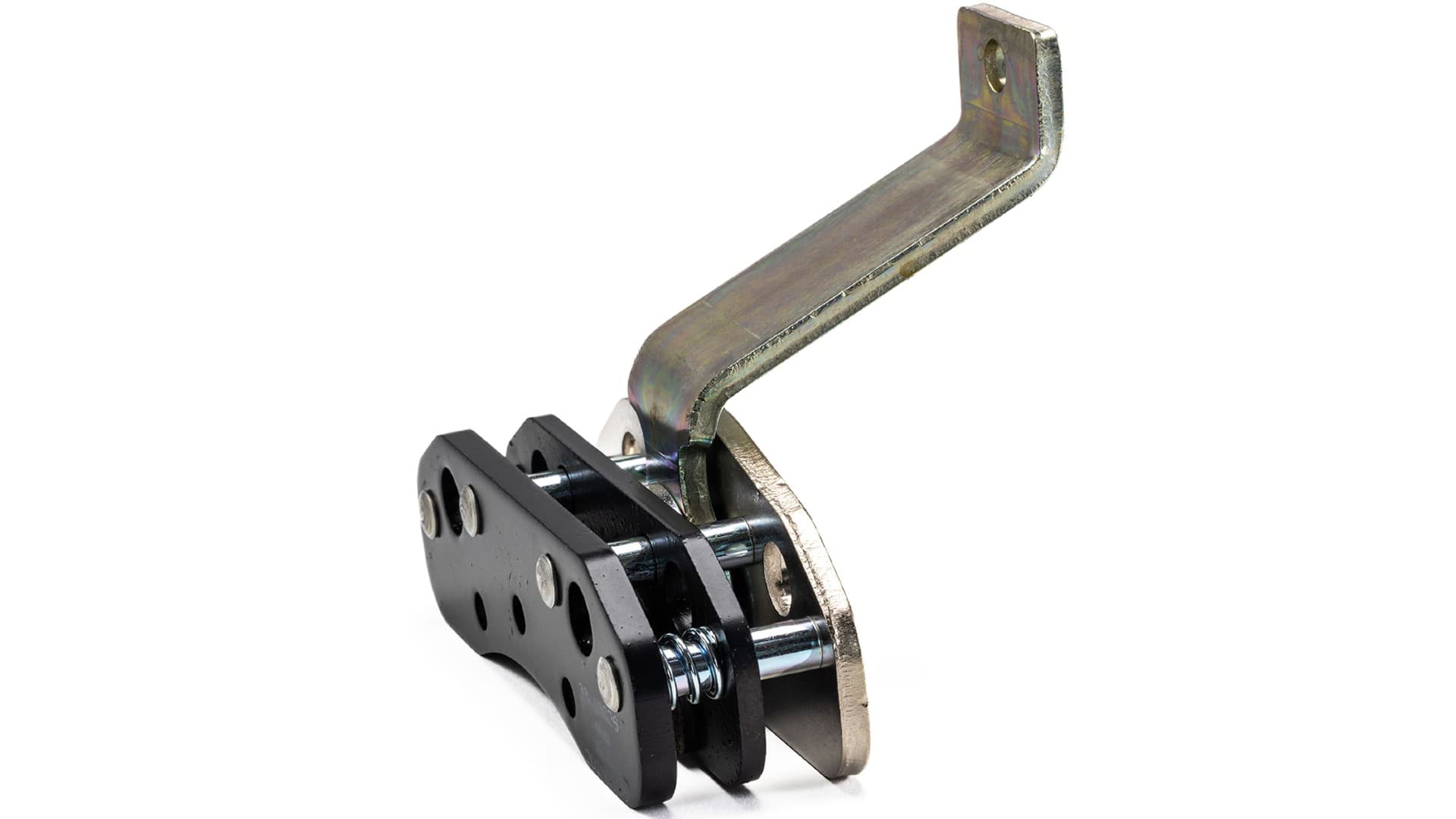

Bison Mechanical Park Brake: Unparalleled Clamp Force & Performance

Larger deck sizes. More powerful engines. Heavier weights and faster speeds. Today’s zero-turn mowers (ZTRs) are bigger and better than they were just a few years ago – so big, in fact, that keeping them securely in place can be a challenge, especially when placed on a trailer or sitting on an incline.

Dry Disc Brakes: How Engineering Impacts Performance & Safety

Dry disc braking systems, when they came into widespread use decades ago, represented a significant improvement over drum brakes. They’ve been used ever since in everything from mountain bikes to heavy-duty military trucks. They’re the most common type of braking system today, primarily because they’re simple, efficient, and reliable.

Retrofitting Brakes on Agriculture Equipment: What You Need to Know

It’s not uncommon for agriculture equipment dealers to upgrade components of their older inventory, especially key components like braking systems. In many cases, it makes a lot of sense: Upgrading older braking systems can improve the equipment’s stopping power, which in turn enhances safety Buyers typically have more confidence purchasing used equipment when its essential components, like brakes, have been swapped for newer versions Dealers can get a higher price for equipment with upgraded systems Older braking systems may not be in top working order, exposing dealers to potential liability Dealers aren’t the only ones realizing the benefits of upgrading and retrofitting. Many original equipment manufacturers (OEMs) offer remanufacturing programs, where they take back used equipment, refurbish it to like-new condition, and then resell it with a warranty. Remanufacturing provides a cost-effective option for equipment buyers, and gives OEMs an additional revenue stream.

Adapting Brake Systems for Autonomous & Electric Vehicles

Today’s vehicle industry, both on- and off-road, is nothing like it was 20 years ago – or even 10 years ago. Two of the more disruptive forces causing change have been government regulation around environmental issues and the growing use of artificial intelligence (AI) to improve vehicle performance. The answer to many of the challenges (and opportunities) brought on by these shifts are electric vehicles (EVs) and autonomous vehicles. EVs and autonomous vehicles aren’t just common on our roads and highways; large corporate farms and massive construction operations are also realizing that they can save money – and help comply with increasing environmental regulations – by putting these types of vehicles to use in their operations. Whatever the application, EVs and autonomous vehicles require special braking systems, with these and other needs factored into their design: Autonomous navigation Handling of battery weight Efficient operation Heat dissipation Noise reduction Government and industry regulation Hayes has led innovation in braking systems for both types of vehicles. The requirements for safety and performance are in some ways similar, and some very different. Let’s take a look.

Hayes Brakes Launches Bison: Turf Industry’s Newest Park Brake

Mequon, Wis. -- Hayes, one of the world’s leading manufacturers of innovative braking systems, is introducing Bison, an industry-leading mechanical parking brake that guarantees stationary placement in a single force. In addition to its use of premium material, Bison’s dependable clamp capability makes this brake unrivaled within the turf vehicle industry.

Hydraulic vs. Mechanical Disc Brakes? Heavy Equipment Needs Both

You’ll typically find two types of brakes on a piece of heavy equipment: hydraulic and mechanical. Why are both needed? Which brakes perform tasks that the other cannot? One type of brake doesn’t satisfy all the performance and safety needs of heavy equipment – both are needed in combination – yet each performs different functions. A garden tractor, for example, uses hydraulic service brakes during normal driving operations to control the vehicle; parking brakes, which are mechanical, are used to keep the vehicle stationary when needed. The chart below outlines the primary features, benefits, and characteristics of both, and how each meets the needs of heavy equipment vehicles.

Collaborative Product Development: How Customized Brake Solutions Give OEMs an Edge

Here’s a team-up that seems out of left field: John Deere and … NASA? It’s true: John Deere collaborated with NASA’s Jet Propulsion Laboratory to create a GPS system that makes self-driving tractors more accurate with reliable, real-time satellite data. It’s a move that could advance agriculture vehicles into a new autonomous age. Success can result when companies work together toward a common goal. Engineering heavy-duty equipment, in particular, demands that everyone brings their best. Sometimes, such projects require looking outside your walls. When available off-the-shelf brakes aren’t cutting it for your vehicle design, it’s time to turn to a partner and work together to find customizations that deliver a tailored solution and provide a competitive advantage.

How Powersports Brakes Manufacturers Can Meet Extreme Demands in Performance

For snowmobile riders, UTV enthusiasts, and anyone else hitting the trails, the U.S. has its share of extremes in weather and terrain — and they’re some of the biggest challenges powersports vehicles face. How can you and your powersports brakes manufacturing partner ensure exceptional performance for your customers in those unrelenting environments?

The Importance of Specialized Off-Road Vehicle Brake Manufacturing

Every off-road vehicle — from riding lawn mowers to wheel loaders and everything in between — is more complex today than it was in years past. Advancements in mechanics and intricate built-in technologies put high demands on every individual component. Let’s focus on the brakes. When considering this critical subsystem, partnering with experts who specialize in it results in a superior performance than what you’d find going it alone or buying from a general parts provider. Specialization: Streamlines development and production Enables greater innovation Controls costs Adds value Here’s how.

How to Improve Disc Brake Performance in Muddy Conditions

Tractors, plows, cultivators, and other agriculture vehicles perform critical work while driving on mud that can damage sensitive equipment. Higher ground clearance helps other components, but working parts closer to the ground are at greater risk. Disc brakes are especially susceptible. Mud is abrasive and can easily splash and cake onto intricate brake components. Rotors and pads wind up scuffed and scratched, especially when the mud dries to more abrasive dirt and rocks.

How to Prevent 5 Common Failures in Dry Disc Brakes

The best way to solve a problem? Prevent it from happening in the first place. While your customers will always be responsible for routinely inspecting and maintaining their brakes throughout ownership, you can give them a head start by equipping your vehicles with high-quality dry disc brake systems that won’t become headaches. Dry disc brakes have become the standard in many industries — heavy equipment (e.g., construction and agriculture vehicles), ATVs, UTVs, turf care vehicles, motorcycles, passenger cars, and more.

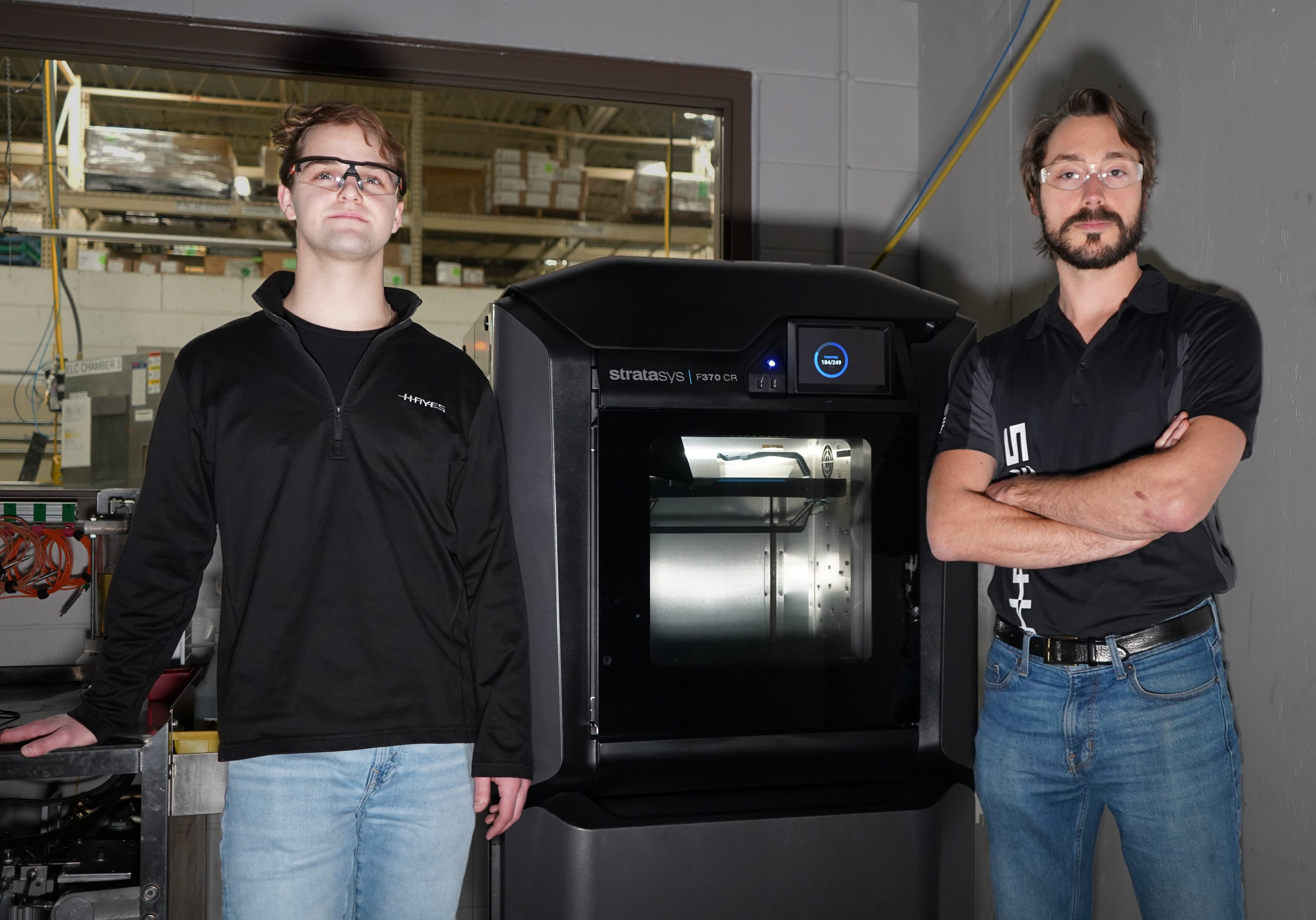

3D Printing Enhances Hayes' In-House Capabilities

At the start of the new year, Hayes Brakes took a significant step forward by enhancing their 3D printing capabilities with state-of-the-art technology. This strategic decision was made to further enhance their product development process, enabling them to be even more agile in creating innovative solutions on tight timelines. With the addition of in-house printing capabilities, Hayes now has a comprehensive range of 3D printing resources at their fingertips.

Custom Brakes vs. Stock Brakes in Turf Care

Turf care vehicles equipped with the wrong brakes put property and rider safety at risk. Each turf care vehicle — from residential riding lawn mowers to golf course fairway mowers — needs brakes that perfectly fit the design and function. Operators count on the brakes to help them move heavy loads, perform precise maneuvers, and maintain control. Most brake manufacturers produce standard, stock brakes that work well in many applications. But here’s why the smart choice is to customize your brakes instead of using stock products for your turf care vehicles.

Hayes CEO Honored as Industry Titan

Hayes Performance Systems is pleased to announce that, for a second year in a row, CEO & President Phil Malliet has been recognized by Titan 100 as one of the 100 notable executives in Wisconsin. The Titan 100 program distinguishes an area’s most accomplished business and non-profit leaders in their industry by demonstrated vision, passion, and exceptional leadership. Phil was recognized alongside industry titans from Wisconsin in Milwaukee on January 18. Upon the receiving the nomination, Phil noted, “I’m honored to have received this honor from Titan 100 yet again. This success is only possible because of the team I’ve built around me, which I consider one of my greatest business successes.”

Spring Applied Hydraulic Release Brake Actuator: 4 Benefits for the Construction Industry

In 1990, Hayes Performance Systems patented its Spring Applied Hydraulic Release, or SAHR, brake actuator (initially called the Spring Applied/Pressure Release Emergency Brake Actuator) as a fail-safe option for construction vehicles. The SAHR has evolved over time, but has always been a remarkably reliable – and critical – component of heavy equipment braking systems. Let’s take a look at how the SAHR works, and its benefits to the construction industry.

How to Maintain Construction Brakes Through Proper Braking Techniques

Construction vehicle brake maintenance involves more than just regular inspections and cleaning. Correct use is vital to their longevity, too. Without proper braking techniques, braking systems on construction vehicles wear out faster, becoming less effective and potentially hazardous at job sites. Let’s look at wear and tear concerns and several crucial ways you can maintain your construction brakes by applying the proper techniques.

Hayes Brakes Launches New Website

December 14, 2023, Mequon, Wis. – Hayes Brakes, a global leader in braking systems, is pleased to announce the official launch of its enhanced and renewed website, www.hayesperformance.com. More than just a tune-up, the new Hayes website is a total reconstruction — complete with intuitive navigation, extensive resources, an educational blog, and much more.

7 Reasons for Brake Failure in Heavy Equipment and How to Avoid Them

Brakes must work, but that doesn’t mean they always do. And when they don’t work when needed in heavy equipment, that puts operations behind schedule and risks profit loss. In most cases, brake failure is preventable. Equip yourself with the knowledge you can bring to your customers and check out these seven common reasons for brake failure, potential causes, and how to avoid them. Design faults Excessive wear & tear Overheating Contamination Imbalance Fluid leaks Electrical issues

Dry Disc Brakes vs. Wet Disc Brakes

Brakes are brakes, right? Not exactly. Two of the most common braking systems — dry disc brakes and wet disc brakes — operate in unique ways and aren’t necessarily interchangeable. Let's explore the pros and cons of dry disc brakes and wet disc brakes, the operation of each, and their common uses. Then, you can decide the best option for your vehicle.

The Importance of a Construction Brake System Inspection

Heavy equipment brakes — particularly in the construction industry — are critical to instantaneously stopping massive amounts of weight and momentum. In a best-case scenario, brake failure can result in a mishap that only delays work; on the other hand, it could result in something far more catastrophic, including loss of life.